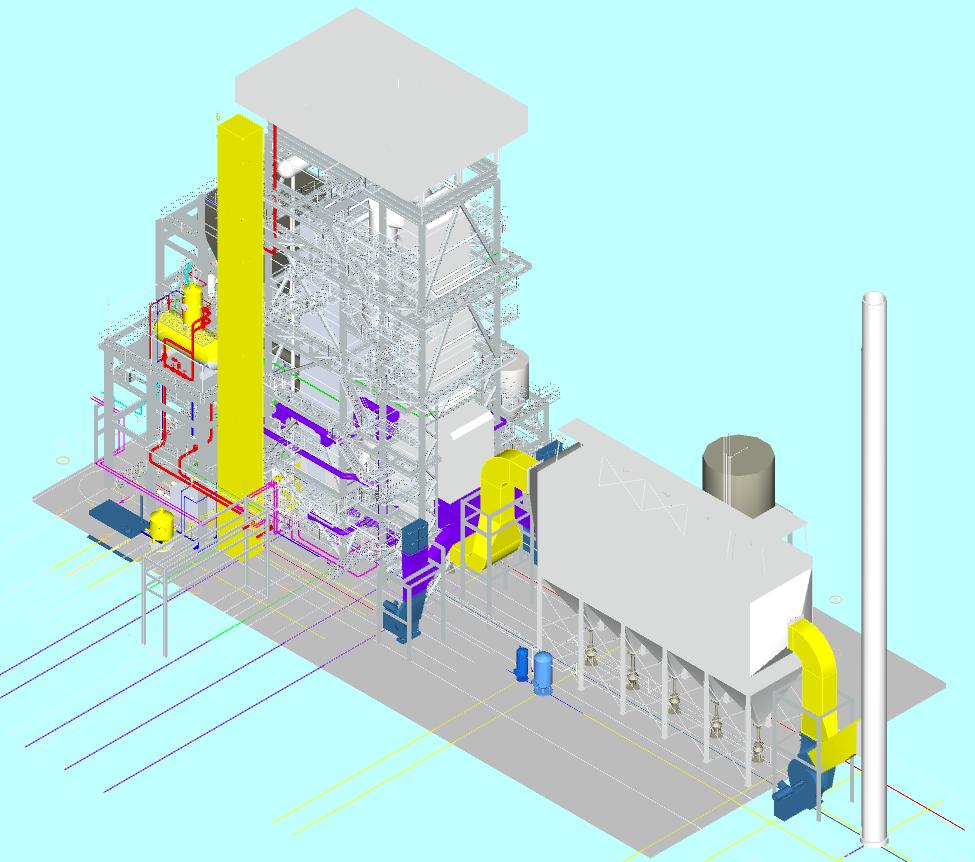

#2 Boiler for Co-generation of Thai Cane Paper Public Company

● Capacity: 1x75t/h circulating fluidized bed boiler and supporting facilities

● Owner: THAI CANE PAPER PUBLIC CO. LIMITED (TCP)

● Construction site: Thamoung District, Kanchanaburi, Thailand

● Project highlight: The materials, design, and manufacturing of pressure vessels and pipelines adopt ASME standards. With full automatic combustion and regulation, it is possible for the boiler to burn coal only and the mixture of bark, sludge, waste paper and residue, etc. SAMA diagram design is provided for automatic control for the first time. The thermal efficiency of boiler in the performance test is greater than 93.5%.

● Project Overview: The project is completed by us for TCP, subsidiary of SCG Group, Thailand, on EPC basis for the construction of a 75t/h bark and coal-fired circulating fluidized bed boiler that supports a 9MW co-generation project. Fuel can be burned separately or mixed with other fuels according to the following calorific value ratios:

Working condition 1: 100% coal

Condition 2: 70% coal+30% bark

Condition 3: 70% coal+13% bark+13% wood chips+4% pulp waste

The boiler generates steam for co-generation by firing the mix of solid waste such as bark, sawdust, sludge, and waste paper generated during the paper and pulp production process, supplementing the factory with heat and electricity, achieving resource utilization, reduction, and harmless treatment.

Company Profile

Company Profile

Organization Structure

Organization Structure

Elite Teams

Elite Teams

Qualification Certificates

Qualification Certificates

Development History

Development History

Social Honors

Social Honors

Personal Honors

Personal Honors

Company News

Company News

Tendering and Bidding Announcements

Tendering and Bidding Announcements

Pulp and Paper Engineering

Pulp and Paper Engineering

Sugar Engineering

Sugar Engineering

Food and Fermentation Engineering

Food and Fermentation Engineering

Grain Storage, Cold Chain Logistics

Grain Storage, Cold Chain Logistics

Pharmaceutical Engineering

Pharmaceutical Engineering

Health and Medical Care

Health and Medical Care

Cultural Education

Cultural Education

Achievements

Achievements

Digital

Digital

Honorary Awards

Honorary Awards